Search

Products

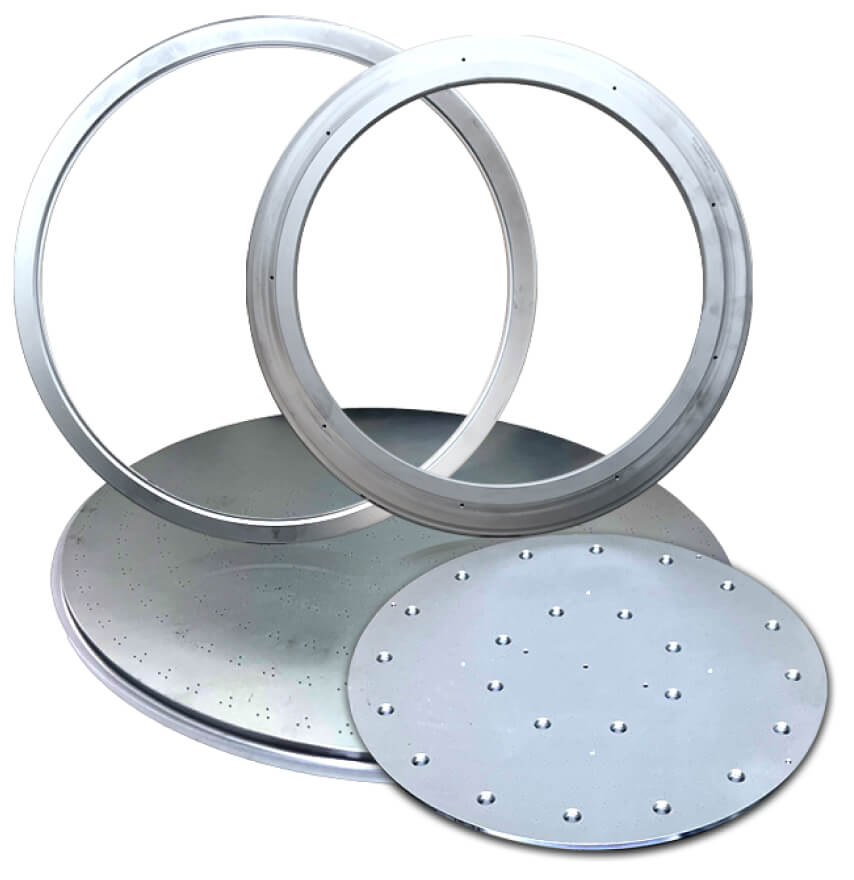

Monocrystalline Silicon Parts

Product Information

A major advantage of Sicreat is the advanced production of monocrystalline silicon components for integrated circuit plasma etching. The monocrystalline silicon components independently developed and produced by us include focus rings, silicon electrodes, silicon trays, and silicon plates used in processes such as photolithography, etching, thin film, and deposition etc., All have been applied in the production processes of many semiconductor manufacturers in China.

Technical Advantages

It adopts MCZ (Superconducting Magnetic Czochralski).

It has a maximum diameter of 485mm.

The impurity content is extremely low.

Zero dislocation defects.

Smooth resistivity uniformity.

High growth yield.

Product Usage

Primary raw materials for wafer etching.

Key materials for IC etching.